Nickel Alloy,Nickel-Based Alloys

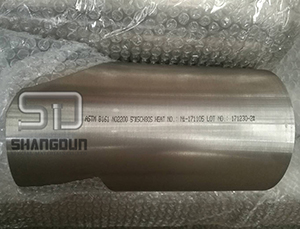

Ⅰ:Nickel& Low Carbon Nickel Alloy seamless tube Standard: SB-163 Grade:N02200, N02201 CHEMICAL COMPOSITION:

|

Standard |

|

material |

Nickel |

Copper |

Iron |

Manganese Max |

Carbon |

Silcon A |

Sulfur Max |

|

SB-163 |

Nickel |

N02200 |

99.0min |

0.25max |

0.40max |

0.35max |

0.15max |

0.35 |

0.01 |

|

SB-163 |

Low C Nickel |

N02201 |

99.0min |

0.25max |

0.40max |

0.35max |

0.02max |

0.35 |

0.01 |

|

|

|

Standard |

|

material |

Tensile Strength,Min PSI (MPa) |

Yield Strength (0.2% offset) Min(Mpa) |

Elongation in 2 in. or 50mm or 4D,Min.,% |

|

SB-163 |

Nickel |

N02200 |

55000 (379) |

15000 (103) |

40 |

|

65000(448) SR |

40000 (276) SR |

15 SR |

|||

|

SB-163 |

Low C Nickel |

N02201 |

50000 (345) |

12000 (83) |

40 |

|

|

|

|

60000 (414) SR |

30000 (207) SR |

15 SR |

Ⅱ:Nickel-Copper Alloy seamless pipe and tube Standard: SB-163 / SB-165 Grade:N04400 CHEMICAL COMPOSITION:

|

Standard |

|

material |

Nickel |

Copper |

Iron |

Manganese Max |

Carbon |

Silcon Max |

Sulfur Max |

|

SB-163/SB-165 |

Nickel-Copper |

N04400 |

63.0min |

28.0-34.0 |

2.5max |

2.0max |

0.3max |

0.5 |

0024 |

MECHANICAL PROPERTIES:

|

Standard |

|

material |

Tensile Strength,Min PSI (MPa) |

Yield Strength (0.2% offset) Min(Mpa) |

Elongation in 2 in. or 50mm or 4D,Min.,% |

|

SB-163 |

Nickel-Copper |

N04400 |

70000 (483) |

28000 (193) |

35 |

|

|

|

|

85000 (586) Stress Relieved |

55000 (379) Stress Relieved |

15 Stress Relieved |

Ⅲ:Nickel-Chromium-Iron Alloy seamless pipe and tube Standard: SB-167 / SB-163Grade:N06600,N06601,N6690 CHEMICAL COMPOSITION:

|

Standard |

|

material |

Nickel |

Chromium |

Iron |

Manganese |

Aluminum | Carbon | Copper | Silicon | Sulfur |

|

SB-167/SB-163 |

Ni-Cr-Iron |

N06600 |

72.0min |

14.0-17.0 |

6.0-10.0 |

1.0max |

0.15max | 0.5max | 0.5max | 0.015max | |

|

SB-167/SB-163 |

Ni-Cr-Iron |

N06601 |

58.0-63.0 |

21.0-25.0 |

remainder |

1.5max |

1.0-1.7 | 0.10max | 1.0max | 0.5max | 0.015max |

|

SB-167/SB-163 |

Ni-Cr-Iron |

N06690 |

58.0min |

27.0-31.0 |

7.0-11.0 |

0.5max |

0.05max | 0.5max | 0.5max | 0.015max |

MECHANICAL PROPERTIES:

|

Standard |

Material |

Tensile Strength,Min PSI (MPa) |

Yield Strength (0.2% offset) Min(Mpa) |

Elongation in 2 in. or 50mm or 4D,Min.,% |

||

|

SB-167/SB-163 |

Ni-Cr-Iron |

N06600 |

80000 (552) |

35000 (241) OD≤127MM,30000(205)OD>127MM |

30 OD≤127MM,35 OD>127MM |

|

|

SB-167/SB-163 |

Ni-Cr-Iron |

N06601 |

80000 (552) |

30000 (207) |

30 |

|

|

SB-167/SB-163 |

Ni-Cr-Iron |

N06690 |

85000 (586) |

35000 (241) |

30 |

|

|

|

Ⅳ:Nickel-Chromium-Molybdenum-Columbium Alloy seamless pipe and tube Standard: SB-444Grade:N06625 CHEMICAL COMPOSITION:

|

Standard |

Material |

Carbon |

Mn |

Silicon |

Phosphorus |

Sulfur |

Chromium |

Cb+Ta |

Cobalt |

Molybdenum |

Iron |

Aluminum |

Titanium |

Copper |

Nickel |

|

SB-444 |

N06625 |

0.10max |

0.50max |

0.50max |

0.015max |

0.015max |

20.0-23.0 |

3.15-4.15 |

1.0max |

8.0-10.0 |

5.0max |

0.40max |

0.40max |

58.0min |

MECHANICAL PROPERTIES:

|

Standard |

|

Material |

Tensile Strength,Min PSI (MPa) |

Yield Strength (0.2% offset) Min(Mpa) |

Elongation in 2 in. or 50mm or 4D,Min.,% |

||||||

|

SB-444 |

Ni-Cr-Mo-Columbium |

N06625 |

100000 (690) |

40000 (276) |

30 |

||||||

|

Ⅴ:Nickel-Iron-Chromium Alloy seamless pipe and tube Standard: SB-163 / SB-407Grade:N08800, N08810,N08811,N08801 CHEMICAL COMPOSITION:

|

Standard |

|

material |

Nickel |

Copper |

Iron | Manganese Max | Carbon | Silcon | Sulfur Max | Chromium | Aluminum | Titanium |

|

SB-163/SB-407 |

Ni-Iron-Cr |

N08800 |

30.0-35.0 |

0.75max |

39.5min | 1.5max | 0.10max | 1.0 | 0.015 | 19.0-23.0 | 0.15-0.60 | 0.15-0.60 |

|

SB-163/SB-407 |

Ni-Iron-Cr |

N08810 |

30.0-35.0 |

0.75max |

39.5min | 1.5max | 0.05-0.10 | 1.0 | 0.015 | 19.0-23.0 | 0.15-0.60 | 0.15-0.60 |

|

SB-163/SB-407 |

Ni-Iron-Cr |

N08811 |

30.0-35.0 |

0.75max |

39.5min | 1.5max | 0.06-0.10 | 1.0 | 0.015 | 19.0-23.0 | 0.15-0.60 | 0.15-0.60 |

|

SB-163/SB-407 |

Ni-Iron-Cr |

N08801 |

30.0-34.0 |

0.5max |

39.5min | 1.5max | 0.10max | 1.0 | 0.015 | 19.0-22.0 | 0.75-1.5 |

MECHANICAL PROPERTIES:

|

|

|

Tensile Strength,Min PSI (MPa) |

Yield Strength (0.2% offset) Min(Mpa) |

Elongation in 2 in. or 50mm or4D,Min.,% |

||||||

|

Standard |

|

material |

||||||||

|

SB-163/SB-407 |

Ni-Iron-Cr |

N08800 |

75000 (520) |

30000 (205) |

30 |

|||||

|

SB-163/SB-407 |

Ni-Iron-Cr |

N08810 |

65000 (450) |

25000 (170) |

30 |

|||||

|

SB-163/SB-407 |

Ni-Iron-Cr |

N08811 |

65000 (450) |

25000 (170) |

30 |

|||||

|

SB-163/SB-407 |

Ni-Iron-Cr |

N08801 |

65000 (450) |

25000 (170) |

30 |

|||||

|

|

|

Ⅵ:Nickel-Iron-Chromium –Molybdenum-Copper Alloy seamless pipe and tube Standard: SB-423 Grade:N08825 CHEMICAL COMPOSITION:

|

Standard |

Material |

Nickel |

Chromium |

Iron |

Manganese |

Carbon |

Copper |

Silicon |

Sulfur |

Aluminum |

Titanium |

Molybdenum |

|

SB-423 |

N08825 |

38.0-46.0 |

19.5-23.5 |

22.0min |

1.0max |

0.05max |

1.5-3.0 |

0.5max |

0.03max |

0.2max |

0.6-1.2 |

2.5-3.5 |

MECHANICAL PROPERTIES:

|

Standard |

|

Material |

Tensile Strength,Min PSI (MPa) |

Yield Strength (0.2% offset) Min(Mpa) |

Elongation in 2 in. or 50mm or 4D,Min.,% |

|

SB-423 |

Ni-Iron-Cr-Mo-Copper |

N08825 |

85000 (586 ) |

35000 (241) |

30 |

|

|

|

Ⅵ:Nickel-Iron-Chromium-Silicon Alloy seamless pipe and tube Standard: SB-535 Grade:N08330,N08332 CHEMICAL COMPOSITION:

|

Standard |

Material |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Cu |

Pb |

Sn |

Fe |

|

SB-535 |

N08330 |

0.08max |

2.00max |

0.03max |

0.03max |

0.75-1.50 |

17.0-20.0 |

34.0-37.0 |

1.00max |

0.005 |

0.025max |

remainder |

|

SB-535 |

N08332 |

0.05-0.10 |

2.00max |

0.03max |

0.03max |

0.75-1.50 |

17.0-20.0 |

34.0-37.0 |

1.00max |

0.005 |

0.025max |

remainder |

MECHANICAL PROPERTIES:

|

Standard |

Material |

Tensile Strength,Min PSI (MPa) |

Yield Strength (0.2% offset) Min(Mpa) |

Elongation in 2 in. or 50mm or 4D,Min.,% |

|

SB-535 |

N08330 |

70000 (483) |

30000(207) |

30 |

|

SB-535 |

N08332 |

67000 (462) |

27000 (186) |

30 |

|

|

Ⅶ: N08028 Alloy seamless pipe and tube Standard: SB-668 Grade:N08028

|

Standard |

Material |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Cu |

Iron |

|

SB-668 |

N08028 |

0.030max |

1.0max |

2.50max |

0.030max |

0.030max |

26.0-28.0 |

30.0-34.0 |

3.0-4.0 |

0.6-1.4 |

Remainder |

MECHANICAL PROPERTIES:

|

Standard |

Material |

Tensile Strength,Min PSI (MPa) |

Yield Strength (0.2% offset) Min(Mpa) |

Elongation in 2 in. or 50mm or 4D,Min.,% |

|

SB-668 |

N08028 |

73000 (500) |

31000(214) |

40 |

|

|

Ⅷ: Nickel-Iron-Chromium-Silicon Alloy seamless pipe and tube Standard: SB-535 Grade:N08330 CHEMICAL COMPOSITION:

|

Standard |

|

Material |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Cu |

Pb |

Sn |

Fe |

|

SB-535 |

Ni-Fe-Cr-Si |

N08330 |

0.08max |

2.00max |

0.03max |

0.03max |

0.75-1.50 |

17.0-20.0 |

34.0-37.0 |

1.00max |

0.005 |

0.025max |

remainder |

MECHANICAL PROPERTIES:

|

Standard |

|

Material |

Tensile Strength,Min PSI (MPa) |

Yield Strength (0.2% offset) Min(Mpa) |

Elongation in 2 in. or 50mm or 4D,Min.,% |

|

SB-535 |

Ni-Fe-Cr-Si |

N08330 |

70000 (483) |

30000(207) |

30 |

|

|

Ⅸ: N08020 Nickel-Alloy Pipe and Tube Standard: SB-729 Grade:N08020 CHEMICAL COMPOSITION:

|

Standard |

Material |

C max |

Mn max |

P max |

S max |

Si max |

Ni |

Cr |

Mo |

Cu |

Cb+Ta |

Nitrogen |

Iron |

|

SB-729 |

N08020 |

0.07 |

2.00 |

0.045 |

0.035 |

1.00 |

32.00-38.00 |

19.00-21.00 |

2.00-3.00 |

3.00-4.00 |

8xC-1.00 |

… |

Remainder |

MECHANICAL PROPERTIES:

|

Standard |

Material |

Tensile Strength,Min PSI (MPa) |

Yield Strength (0.2% offset) Min(Mpa) |

Elongation in 2 in. or 50mm or 4D,Min.,% |

|

SB-729 |

N08020 |

80000 (550) |

35000(240) |

30.0 |

Ⅹ: Low Carbon Ni-Cr-Mo Alloy pipe and tube Standard: SB-622 grade:N10276, N06022 CHEMICAL COMPOSITION:

|

Standard |

|

Material |

Ni |

Cr |

Mo |

Fe |

W |

C |

Si max |

Co |

Mn |

V |

P max |

S max |

|

SB-622 |

Low C Ni-Cr-Mo Alloys |

N10276 |

remainder |

14.5-16.5 |

15.0-17.0 |

4.0-7.0 |

3.0-4.5 |

0.010max |

0.08 |

2.5max |

1,0max |

0.35max |

0.04 |

0.03 |

|

SB-622 |

Low C Ni-Cr-Mo Alloys |

N06022 |

remainder |

20.0-22.5 |

12.5-14,5 |

2.0-6.0 |

2.5-3.5 |

0.015max |

0.08 |

2.5max |

0.5max |

0.35max |

0.02 |

0.02 |

MECHANICAL PROPERTIES:

|

Standard |

Material |

Tensile Strength,Min PSI (MPa) |

Yield Strength (0.2% offset) Min(Mpa) |

Elongation in 2 in. or 50mm or 4D,Min.,% |

|

SB-622 |

N10276 |

100000 (690) |

41000(283) |

40.0 |

|

SB-622 |

N06022 |

100000 (690) |

45000(310) |

45.0 |

|

|

Ⅺ:N08904,N8925,N08926 seamless pipe and tube Standard: SB-677 Grade:N08904,N8925,N08926 CHEMICAL COMPOSITION:

|

Standard |

Material |

Carbon max |

Manganese,max |

Phosphorus,max |

Sulfur,max |

Silicon,max |

Nicekl |

Chromium |

Molybdenum |

Copper |

Nitrogen |

Iron |

|

SB-677 |

N08904 |

0.020 |

2.0 |

0.045 |

0.035 |

1.00 |

23.0-28.0 |

19.0-23.0 |

4.0-5.0 |

1.0-2.0 |

bal |

|

|

SB-677 |

N08925 |

0.020 |

1.0 |

0.045 |

0.030 |

0.50 |

24.0-26.0 |

19.0-21.0 |

6.0-7.0 |

0.8-1.5 |

0.1-0.2 |

bal |

|

SB-677 |

N08926 |

0.020 |

2.00 |

0.03 |

0.01 |

0.5 |

24.00-26.00 |

19.00-21.00 |

6.0-7.0 |

0.5-1.5 |

0.15-0.25 |

bal |

MECHANICAL PROPERTIES:

|

Standard |

Material |

Tensile Strength,Min PSI (MPa) |

Yield Strength (0.2% offset) Min(Mpa) |

Elongation in 2 in. or 50mm or 4D,Min.,% |

|

SB-677 |

N08904 |

71000 (490) |

31000 (220) |

35 |

|

SB-677 |

N08925 |

87000 (600) |

43000 (300) |

40 |

|

SB-677 |

N08926 |

94000 (650) |

43000 (295) |

35 |

|

Other grade of s are available as your detail as like N06617,N06219,N06025,N06045,N06603,N06686,N07718,N07750,N08120,N08221,N08020,N08024,N08026, N08031,N08332,N08366,N08367,N10001,N10665,N06022,N10276,etc.

|

|

More grades:

Nickel Alloy: N02200 / 200 N02201 / 201 Nickel-Copper Alloy: N04400 / monel400 Ni-Mo Alloy:N10001 / Hastelloy B N10665 / Hastelloy B-2 N10675 N10629 N10624 Ni-Mo-Cr-Fe: N10003 / Hastelloy N N10004 / Hastelloy W N10242 N06210 Ni-Co-Cr-Si: N12160 Ni-Cr-Fe: N06600 / 600 N06601 / 601 N06617 / 617 N06690 N06025 N06045 N06603 N06693 Ni-Cr-Mo: N06058 N06059 N10002 / Hastelloy C N10276 / Hastelloy C-276 N06022 N06035 N06455 / Hastelloy / C-4 Ni-Cr-Mo-W: N06686 Ni-Cr-W-Mo: N06230 Ni-Cr-Mo-Cb: N06852 N06625 Ni-Cr-Mo-Si: N06219 Ni-Cr-Fe-Mo-Cu: N06007 N06975 N06985 N06030 N06255 N07718 N07750 N06250 Ni-Fe-Cr: N08120 N08800 N08810 N08811 N08801 N08020 / Carpenter 20 Ni-Fe-Cr-Mo: N06002 N06060 N08320 N08135 Ni-Fe-Cr-Mo-Cu: N08031 / Alloy 31 N08535 N08825 N08221 N08028 N08026 N08024 Ni-Fe-Cr-Co: R30556 Ni-Fe-Cr-Si: N08330 N08332

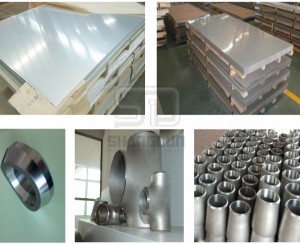

Type of products:

Pipe and tube U-Tube Bars Butting weld fitting Flange or forgings