Super duplex and duplex stainless steel

A790/A790M Specification for seamless and welded ferritic and austenititc stainless steel pipe

A789/A789M Specification for seamless and welded ferritic and austenitic stainless steel tubing for general service

EN10216-5: Seamless steel tubes for pressure purposes

Super Duplex S32750 / F53 S32760 / F55 S32707

Duplex S31803 / F51 S32205 / F60 S31500

|

Material |

C |

Mn |

P |

S |

Si |

Ni |

Cr |

Mo |

N |

Cu |

Others |

|

S31803 |

0.030 |

2.00 |

0.030 |

0.020 |

1.00 |

4.5-6.5 |

21.0-23.0 |

2.5-3.5 |

0.08-0.20 |

||

|

1.4462 |

0.030 |

2.00 |

0.035 |

0.015 |

1.00 |

4.5-6.5 |

21.0-23.0 |

2.5-3.5 |

0.10-0.22 |

- |

|

|

S32205 |

0.030 |

2.00 |

0.030 |

0.020 |

1.00 |

4.5-6.5 |

22.0-23.0 |

3.0-3.5 |

0.14-0.20 |

||

|

1.4362 |

0.030 |

2.00 |

0.035 |

0.015 |

1.00 |

3.50-5.50 |

22.0-24.0 |

0.10-0.60 |

0.05-0.2 |

0.10-0.60 |

|

|

S32750 |

0.030 |

1.20 |

0.035 |

0.020 |

0.80 |

6.0-8.0 |

24.0-26.0 |

3.0-5.0 |

0.24-0.32 |

0.5max |

|

|

1.4507 |

0.030 |

2.00 |

0.035 |

0.015 |

0.70 |

5.50-7.50 |

24.0-26.0 |

2.7-4.0 |

0.15-0.3 |

1.0-2.50 |

|

|

S32760 |

0.050 |

1.00 |

0.030 |

0.010 |

1.00 |

6.0-8.0 |

24.0-26.0 |

3.0-4.0 |

0.20-0.30 |

0.50-1.00 |

w 0.50-1.00 / 40min(B) |

|

1.4501 |

0.030 |

1.00 |

0.035 |

0.015 |

1.00 |

6.0-8.0 |

24.0-26.0 |

3.0-4.0 |

0.20-0.30 |

0.50-1.00 |

W:0.50to1.00 |

|

|

- Designed to combine improved resistance to stress corrosion cracking, pitting, crevice corrosion and high strength when compared with other stainless alloys

- Features:

- Higher strength than standard stainless steels

- Higher corrosion resistance than 316 stainless steel in a wide variety of corrosive Chemicals including sulphuric, phosphoric and nitric acids

- Good resistance to pitting and crevice corrosion in seawater

- High stress corrosion resistance

- Lower thermal expansion than austenitic stainless steels

- Higher thermal conductivity than austenitic stainless steel

Type of products:

Pipe and tube

U-Tube

Square

Rectangle

Butting weld fitting

Flange

Super duplex,Duplex stainless steel

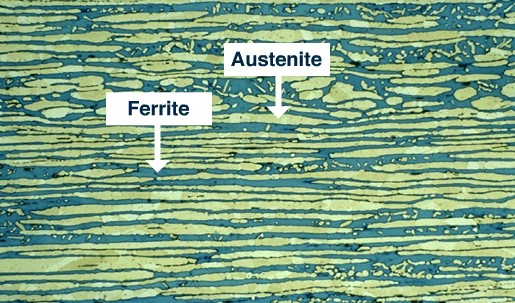

Duplex stainless steels are called “duplex” because they have a two-phase microstructure consisting of grains of ferritic and austenitic stainless steel. The picture shows the yellow austenitic phase as “islands” surrounded by the blue ferritic phase. When duplex stainless steel is melted it solidifies from the liquid phase to a completely ferritic structure. As the material cools to room temperature, about half of the ferritic grains transform to austenitic grains (“islands”). The result is a microstructure of roughly 50% austenite and 50% ferrite.

Duplex stainless steels have a two-phase microstructure of austenite and ferrite grains with high chromium and low nickel contents. This gives duplex stainless steels microstructures that include both austenitic and ferritic phases. They include alloy like 2304 and 2205. These alloys are so named due to their respective compositions-23%, 4% nickel and 22% chromium, 5% nickel.

By having both austenite and ferrite in the microstructure, duplex stainless steels feature properties of both classes. Although a compromise between the two ‘pure’ types, duplex grades can offer some unique property solutions. Duplex grades are resistant to stress corrosion cracking. Duplex grades are resistant to stress corrosion cracking, but not to the same level as ferritic grades. The toughness of duplex grades is superior to that of the ferritic grades- but inferior to that of the austenitic grades.

The duplex structure gives this family of stainless steels a combination of attractive properties:

Strength: Duplex stainless steels are about twice as strong as regular austenitic or ferritic stainless steels.

Toughness and ductility: Duplex stainless steels have significantly better toughness and ductility than ferritic grades; however, they do not reach the excellent values of austenitic grades.

Corrosion resistance: As with all stainless steels, corrosion resistance depends mostly on the composition of the stainless steel. For chloride pitting and crevice corrosion resistance, their chromium, molybdenum and nitrogen content are most important. Duplex stainless steel grades have a range of corrosion resistance, similar to the range for austenitic stainless steels, i.e from Type 304 or 316 (e.g. LDX 2101©) to 6% molybdenum (e.g. SAF 2507©) stainless steels.

Stress corrosion cracking resistance: Duplex stainless steels show very good stress corrosion cracking (SCC) resistance, a property they have “inherited” from the ferritic side. SCC can be a problem under certain circumstances (chlorides, humidity, elevated temperature) for standard austenitics such as Types 304 and 316.

Cost: Duplex stainless steels have lower nickel and molybdenum contents than their austenitic counterparts of similar corrosion resistance. Due to the lower alloying content, duplex stainless steels can be lower in cost, especially in times of high alloy surcharges. Additionally, it may often be possible to reduce the section thickness of duplex stainless steel, due to its increased yield strength compared to austenitic stainless steel. The combination can lead to significant cost and weight savings compared to a solution in austenitic stainless steels.